Applied Flow Technology Fathom 13.0 (1100.0) Win x64

Posted on 20 Sep 10:08 | by Apple | 1 views

Free Download Applied Flow Technology Fathom 13.0 (1100.0) | 448.2 mb

Owner:Applied Flow Technology (AFT)

Product Name:Fathom

Version:13.0 (1100.0)

Supported Architectures:x64

Website Home Page :www.aft.com

Languages Supported:english

System Requirements:Windows *

Size:448.2 mb

Applied Flow Technology (ATF) announced the release ofFathom 13.0 (1100.0)is fluid dynamic simulation software for engineers, used to calculate pressure drop and pipe flow distribution in liquid and low-velocity gas piping and ducting systems.

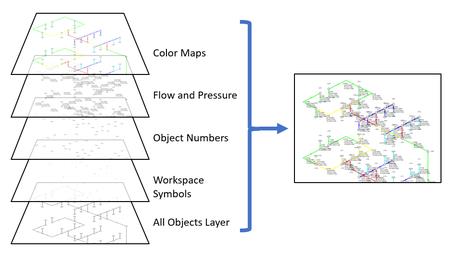

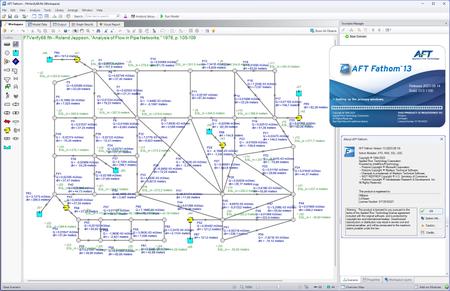

Workspace Layers

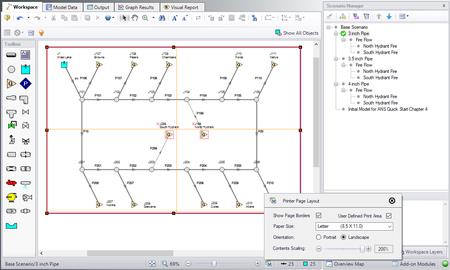

The Workspace Layers feature provides a powerful new tool for customizing and viewing model appearance, input data, and results - all in one place. The Workspace Layers toolset significantly enhances the model building process, providing unparalleled customization options. You can easily update pipe/junction size, color, display text, visibility, and more from a centralized location on the Quick Access Panel. Workspace Layers surpass the capabilities of the previous Visual Report feature. With Layer Settings, you now have easy control over Color Mapping and the visibility of both Input and Output parameters. Any change you make to these settings will have an immediate impact on the model's display, providing real-time feedback. The dynamic combination of unique Layers offers an incredibly flexible framework, allowing you to display precisely what you desire on the Workspace. You can easily toggle the visibility of individual layers on or off, and the state of all layers can be saved to a Layer Preset for future use.

Figure 1: Workspace Layers can display input and output values superimposed over the model, show Color Maps, and control visibility of objects

4-Component Slurry Model

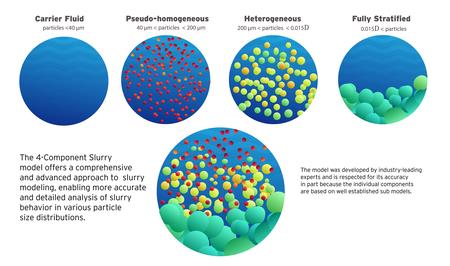

A new 4-Component Slurry Model for the SSL module, developed by leading industry experts, captures complex slurry regimes more accurately. The 4-Component Model introduces a division of slurry solids into four distinct groups, or components, based on the particle size distribution. Each component corresponds to a specific slurry behavior; Carrier Fluid, Pseudo-homogeneous, Heterogeneous, or Fully Stratified. Unlike simpler models that account for only one or two slurry regimes, the 4-Component Model greatly enhances modeling flexibility by automatically determining the effects contributed by each component regime. The model was developed by industry-leading experts and is respected for its accuracy in part because the individual components are based on well established sub models. The 4-Component Model offers a comprehensive and advanced approach to slurry modeling, enabling more accurate and detailed analysis of slurry behavior in various particle size distributions.

Figure 2: The 4-Component Slurry Model considers combined effects from four slurry regimes

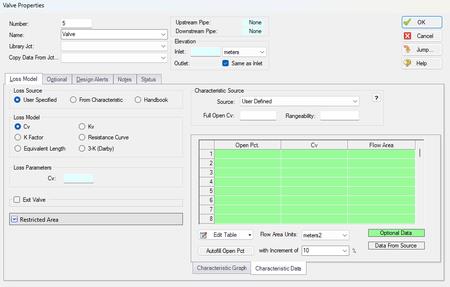

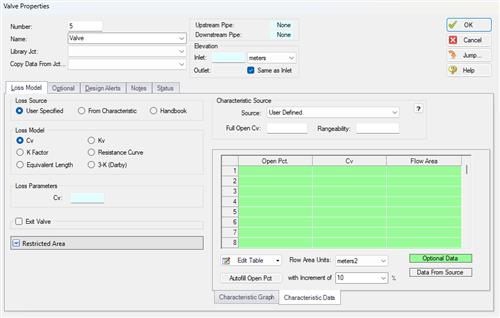

Improved Valve Properties Window

The new Valve Properties window greatly enhances clarity and usability when it comes to modeling valves. The window now clearly distinguishes between different data sources such as User Specified, Characteristic, or Handbook, making it easier to understand the available options. The form has been streamlined to focus on the most essential data, providing a clear understanding of what is required to define a valve accurately. Valve Characteristics, represented by an Open Percent vs. Flow Coefficient table, have been brought front and center. While using a Characteristic is optional, it is highly recommended as it ensures that the valve behavior aligns with real-world scenarios, particularly for valve transients. The process of selecting a pre-defined Characteristic Source has been simplified, which helps obtain more accurate values in case manufacturer data is unavailable.

xApplied Flow Technology Fathom 13.0 (1100.0)

Close

Figure 3: Redesigned Valve Properties window

Streamlined Design Alerts

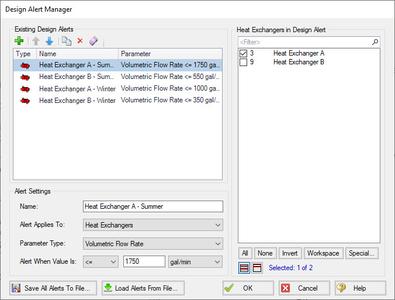

The Design Alert Manager has been reorganized to improve the process of creating and applying user-defined alerts. Now, you can effortlessly create or edit a Design Alert with just a few clicks. As you modify settings, you will immediately see the criteria you are applying, ensuring a transparent experience. We have also reduced the amount of text on the form, while ensuring grammatical clarity. These improvements aim to make it easier to understand the limits being placed on the design.

Figure 4: Steamlined Design Alerts Manager

Other Notable Features

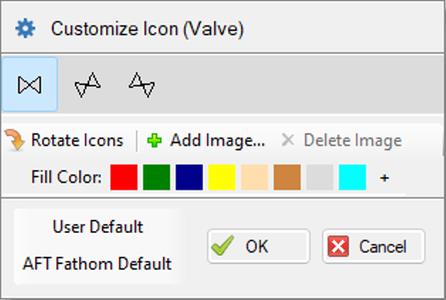

-Custom Junction Icons- Use your own images for junction icons. Utilize any image as a junction icon, simply by right-clicking on the Toolbox icon for the junction, selecting Add Image, and browsing to the image file. This functionality enables you to use standard P&ID icons or custom images to visually represent your equipment. By using recognizable icons, you can improve the clarity and comprehension of model results, especially for those who may not be familiar with the default AFT junction icons.

Figure 5: The Customize Icon window allows a custom image to be applied to any junction

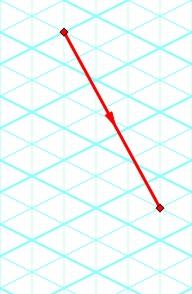

-Isometric Freeform Drawing Mode- Draw on the isometric grid without forcing any particular pipe routing. The Isometric drawing tools have been enhanced by adding a new Isometric Freeform drawing mode. This new drawing mode allows you to snap junction and pipe anchors to the Isometric grid, while having the flexibility to draw pipes that do not necessarily align with the isometric gridlines. This allows you to easily draw complex systems where not all piping follows a Cartesian direction.

Figure 6: Isometric Freeform drawing mode does not force pipes to follow gridlines

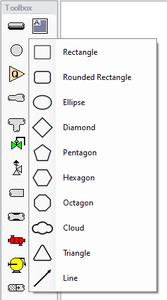

-New Annotations- There are new shapes and a line tool, along with a more advanced Annotation editing panel. New Annotation shapes and a line tool have been introduced to allow more flexible markup such as revision numbers or change requests. Editing of Annotations has been revamped with the introduction of a live-edit Quick Access Panel, which provides immediate visual feedback of the changes you make, and simple global editing of all selected Annotations. The new edit panel also offers expanded functionality, providing you with more customization than was possible in the past.

Figure 7: New Annotation options

-Set Workspace Print Area- Show printing page borders on the Workspace and customize the printing area. The new Printer Page Layout tool offers a convenient and effortless way to adjust the printing area according to your preferences. With a clear and intuitive visual representation, you can easily identify where page breaks will occur. Now, you can confidently print a specific section or the entire model at your desired scale, eliminating the need for trial and error.

Figure 8: The Printer Page Layout feature allows the user to set the Workspace print area

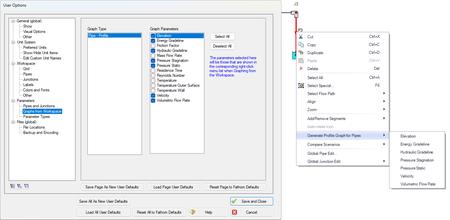

-Customize Parameters Available to Graph from the Workspace- New User Options allow custom selection of any graph parameter on the right-click Workspace context menu. Did you know you can easily graph results from the Workspace by right-clicking on a pipe or junction? This functionality has existed for a long time, but it was previously limited to a predefined set of parameters. Now, you can specify what graph types you would like to see in these menus to simplify your analysis process.

Figure 9: The right-click context menu for pipes on the Workspace can have the graphing parameter options modified

Miscellaneous Improvements

Modeling Additions and Improvements

- Laminar Corrections - Laminar corrections are now off by default, messages indicate if they were applied or are recommend, and output parameters indicate the correction strength.

- Prevent Backflow at Sprays - New "No Inflow" Special Condition for Spray junctions.

- Zero-Length Connectors - Zero-Length Connectors now behave like standard pipes for most features, including selection and graphing tools.

- Fluid Libraries - New category for user-defined fluids, making it easier to find custom entries.

Importing of PCF, EPANET, GIS, and CAESAR II Models

- Bend r/D - Import PCF bends with appropriate r/D values.

- Speed Increase - Importing is up to 10x faster in some cases.

- Defaults and Display - Better defaults and display options for imported models.

- Pipe Materials - Improved ability to link AFT pipe materials to imported pipes.

- CAESAR II Node Names - Display imported CAESAR II node names as junction names.

Behind the Scenes Improvements

- Graphing Optimization - Significant improvements to backend graphing code which provides additional stability now and more capabilities in the future.

- eLicense Access Improvements - Added a "heartbeat" functionality to eLicenses which improves security and the release of license seats not in use.

- Output - Significant improvements to backend output code which provides additional stability now and more capabilities in the future.

- Timed Recovery File - Automatically generate a backup of your unsaved model that can be used to recover unsaved work in the event of unexpected application closure. This is separate from the *.bak files which are only generated after saving a model.

New and Improved Output Parameters and Messages

- Pump RPM - Report pump speed in RPM, in addition to percent.

- Dimensionless Heat Transfer Parameters - Grashof, Nusselt, Prandtl, and Rayleigh Numbers have been added as Output parameters.

- Deep Laminar Caution - Simple loss models do not account for exceptionally low laminar flow, this new message provides a caution if you enter this range.

- POR/AOR in Pump Summary - Show the values for Preferred and Allowed Operating Ranges in the Pump Summary.

- Event Messages in New Format - Events are now shown in a cleaner, collapsible format similar to Warnings.

- XTS Module Tank Overflow and Drain Warnings - New messages to clearly indicate if a Tank has overflowed or drained during the transient.

Fathomis fluid dynamic simulation software used by engineers in over 80 countries to calculate pressure drop and flow distribution in liquid and low velocity gas piping and ducting systems. Fathom helps engineers understand their piping system and predict how pipes, valves, pumps and other components interact with each other. It allows them to easily model, analyze and simulate their systems in order to evaluate the performance of new designs and assure all design requirements are met. Fathom truly helps engineers accurately select and size components, so they can produce less costly and more reliable piping systems.

AFT Fathom - Overview

Founded in 1993,Applied Flow Technologyis a leader in the pipe flow modeling software market. With a primary focus on developing high quality fluid flow analysis software, AFT has a comprehensive line of products for the analysis and design of piping and ducting systems.

Links are Interchangeable - No Password - Single Extraction

Related News

System Comment

Information

Users of Visitor are not allowed to comment this publication.

Users of Visitor are not allowed to comment this publication.

Facebook Comment

Member Area

Top News